JCB Powertrain is taking the wraps off an all-new derivative of its new DualTech VT transmission at ConExpo in March. It will be the first time the technology has been sold to third party customers since it was first unveiled to wide acclaim in JCB machines in 2016.

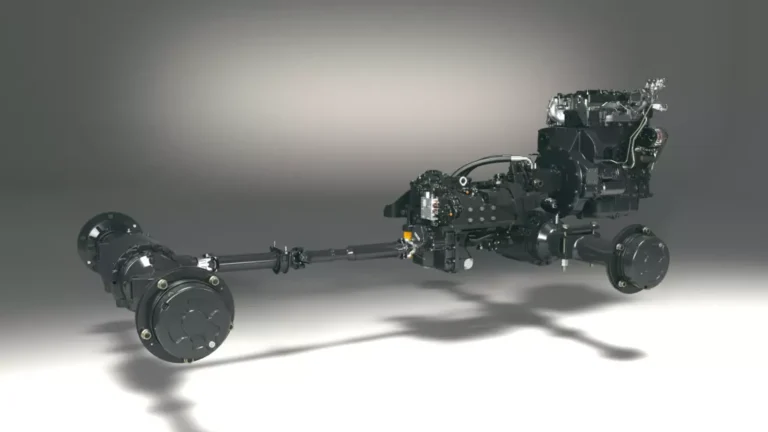

The new DualTech VT is a 2-speed transmission that JCB says combines the benefits of hydrostatic and powershift technologies in the same unit. Based on JCB’s DualTech Variable Transmission used in heavy-duty agricultural telescopic handlers, this version has been reengineered into a more traditional inline layout, making it ideally suited to wheeled machines with conventional drivetrain architecture.

DualTech VT provides hydrostatic drive up to 25kph, delivering low-speed control for applications such as loading, handling and yard work. Above 25kph it transitions to direct mechanical drive, providing high-speed travel up to 40kph. This makes it ideal for machines that require low-speed precision alongside long-distance capability, including construction support vehicles, specialist agricultural equipment and municipal fleet machines. Another notable feature is the integrated Spring Applied Hydraulic Retract (SAHR) and cable park brake options, which supports an optimised driveline package.

“It’s an all-new design and package, tailored initially for the recently launched JCB TM280 loading shovel model. However, due to its compact design, this new derivative of DualTech VT could be integrated to a number of OEM applications and deliver a ‘best of both worlds’ combination of low-speed hydrostatic controllability combined with a seamless handover to direct mechanical drive,” says Jon McNulty, JCB Powertrain global sales and applications manager.

The DualTech VT transmission will be joined by another key transmission launch, the SS670 synchro shuttle transmission. Replacing the SS600, SS700 and SS750, the new SS670 Synchro-Shuttle transmission is designed for simple, cost-effective driveline configurations. The company says it delivers performance improvements via the W300 torque converter and latest synchroniser technology. The design is also optimised to minimise churning losses and enhance efficiency.

It was developed initially for JCB site dumpers, backhoe loaders and rough-terrain forklifts; however, the company says the SS670 package provides attributes for a wide range of off-highway applications.

“These two new launches complete a competitive and robust range of transmission technology solutions and join the Powershift (PS900) transmission and hydrostatic (TG172) dropbox which, combined with JCB’s Powertrain’s comprehensive axle and engine portfolio, can support full powertrain package solutions for a vast range of OEM applications,” says McNulty.

Also making an appearance on the JCB Powertrain stand will be JCB’s hydrogen engine. JCB is the first construction OEM to develop a fully approved hydrogen combustion engine. A team of 150 engineers has been working on the £100 million programme for nearly four years, and more than 150 evaluation engines have already been produced, powering backhoe loaders and loadall telescopic handlers.

Image: JCB Powertrain