The Universal Angular Sensor (UAS) from Forvia Hella is a newly developed modular rotary angle sensor for precise and reliable measurement of angular positions in vehicles and agricultural machinery

The Universal Angular Sensor (UAS) uses proven CIPOS technology (Contactless Inductive Position Sensor), which enables a contactless, inductive measuring principle. This means that the sensor operates without wear and is extremely resistant to external magnetic fields and interference, even under extreme conditions. With its combination of high precision, flexibility and robustness, the UAS sets new standards in modern angle measurement across numerous off-highway applications.

“Thanks to proven CIPOS technology, our new rotary angle sensor meets the industry’s need for robust and modular measurement solutions. Here, we draw on our experience from the more than 1 billion CIPOS sensors produced to date, which are successfully used in a wide variety of applications,” says Dr. Fabian Utermöhlen, vice president sales & marketing in the Lifecycle Solutions Business Group at Forvia Hella.

With series production planned for 2026, Forvia Hella is responding specifically to the growing demand for detecting different levels as well as precise, reliable angle and inclination measurement while reducing installation costs.

What sets this sensor apart?

The UAS features versatile technical properties that enable flexible adaptation to various application scenarios. The basic principle is based on a contactless, inductive measuring method (CIPOS), which uses alternating electromagnetic fields to detect angular positions with high precision.

Thanks to its modular design, the sensor can be flexibly adapted to specific requirements.

Mechanically, the sensor consists of a base sensor that can be configured with different rotor elements, circuit boards and connections as required. This modular design allows different lever arms or profiled shaft connections, fasteners and further connectors to be combined so that the sensor can be optimally adapted to the respective installation situation. The measuring angle range, communication interface, signal resolution and even the nominal voltage can also be defined according to customer specifications to ensure seamless integration into existing systems. This modular design reduces development effort and installation costs. The robust design with IP6K9K protection allows usage in environments with dirt, dust, water and high mechanical loads without impairing the sensor function.

Efficient position measurement

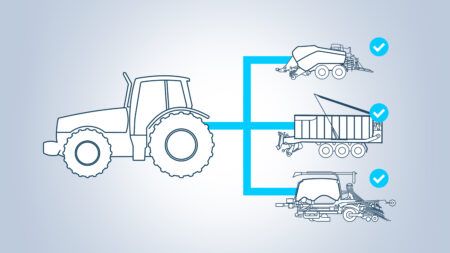

The UAS from Forvia Hella offers numerous applications in agriculture, ranging from precise machine control to system monitoring. The UAS can be used for the measurement and control of steering systems in tractors and agricultural machinery. It can detect the exact position of the steering wheels, enabling precise control of the vehicles. This is particularly important for automatic steering systems that require a high level of accuracy.

Another use of the UAS is for monitoring the position of flaps or doors in stables and granaries. The sensor can monitor the position of flaps or doors to ensure that they are properly opened or closed. This is important for ventilation and protection of stored crops.

Moreover, the UAS can monitor and control hydraulic cylinders on harvesting machines. The sensor can monitor the position of hydraulic cylinders responsible for raising and lowering cutting units or other attachments. This ensures optimum performance and prevents damage to the machines.

A strong electronics portfolio

With the UAS, Forvia Hella is expanding its electronics portfolio for off-highway customers, which includes sensors, control units, actuators and lighting electronics. These solutions combined meet the demands of modern machines – with a focus on efficiency, safety, sustainability and design. The UAS is an advanced solution for precise position measurement. With series production scheduled to start in 2026, the team are now discussing details.

Image: Forvia Hella