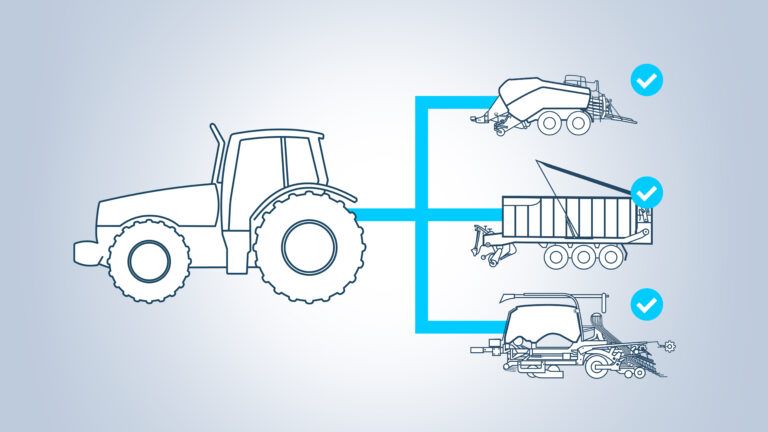

Implements take the lead in work processes and demand optimal hydraulic performance for the respective work task. With the next generation of hydraulic systems, Bosch Rexroth has consistently developed this approach and opens up new degrees of freedom with Electronic load sensing ELS. Thanks to the eOC (electronic Open Circuit) variable piston pumps, the hydraulic performance can be flexibly adapted to the requirements of various implements. The advantages for the end-user: simplified operation, highly automated workflows with consistent or even better quality, and higher productivity with improved energy efficiency.

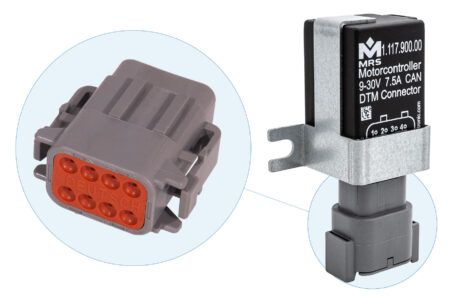

Up to now, the hydraulic requirements of implements have usually been sent to the tractor hydraulics via hydraulic load sensing pilot lines. With Electronic load sensing ELS, all consumers digitally at the same time communicate their requirements for pressure, oil flow, and response time to the BODAS control unit. The Software running on the BODAS control unit controls then the electronically controlled variable displacement piston pump (eOC-P) according to the demand values in an electronical closed loop.

Optimal conditions for highly automated work

In contrast to previous concepts, Electronic load sensing ELS hydraulic systems are not limited by a pump factory-setup. With eOC, Bosch Rexroth shifts the variance into Software. This shortens engineering times for machine manufacturers and saves installation space by eliminating previously necessary hydraulic lines and components. Above all, the respective implements now determine the tractor pump pressure, oil flow, and response times, thus ensuring optimal work results. At the same time, the advanced eOC system approach, featuring pumps, ECUs, and electro-hydraulic valves, establishes the foundation for future highly automated operations, like baling. Here, TIM-capable attachments automatically ensure the exact adherence to the diameter and weight of the bales and automatically stop the tractor to deposit the bales.

Higher energy efficiency and availability

The eOC system automatically compensates for line losses to increase productivity. The reduced power loss in standby and the adjustable stand-by pressure improve energy efficiency and reduce operating noise. Thanks to the Electronic load sensing ELS system architecture the pressure signals from all components are digitally acquired and digitally sent to the electronically controlled pump. With the acquisition of Hydraforce in 2023, Bosch Rexroth offers now an extensive program of compact valves that completes the hydraulic tractor’s system in a space-saving and efficient manner. Bosch Rexroth thus provides the most comprehensive range of motion control systems, which includes hydraulic screw-in cartridges, manifold blocks, and electronic controls with corresponding software.

A full eOC hydraulic system architecture, enable machine manufacturers to develop new diagnosis and service strategies of the hydraulic system. If required, eOC pumps can be set up to new parameters over the air.

Image: Bosch Rexroth