New electrification solutions from Danfoss are addressing efficiency limitations in mobile elevating work platforms and other light-duty vehicles

In electrified machinery, efficiency matters. The more efficient the subsystems, the longer the machine can operate on a single charge. If runtime is not an issue, increasing efficiency can reduce the amount of batteries required, thereby reducing the upfront cost as well as the total cost of ownership of the machine.

Whether working with low- or high-power machinery, OEMs are focused on increasing efficiency. Electrification started in low-voltage machines decades ago, so it’s easy to overlook those applications as key targets for optimisation. But OEMs specialising in low-voltage machinery, such as mobile elevating work platforms (MEWPs), have identified technology limitations, and system efficiency is falling short of customer requirements.

Danfoss saw a major opportunity to improve on these shortcomings. Danfoss Editron has consistently been at the forefront of the electrification transition in heavy-duty machinery, with solutions that help OEMs reduce emissions, lower operating costs and improve operator conditions. Editron recently launched a portfolio of low-voltage products, encompassing 24- and 48- volt solutions, enabling the company to support electrification across a broader power range. These solutions, including the ePowerpack and eDrive systems, are helping OEMs unlock the complete benefits of electrification.

Designed for MEWPs, automated guided vehicles and other low-power, light-duty vehicles, Editron’s integrated low-voltage systems maximise efficiency, offer a very compact form factor, simplify machine design, integrate easily with hydraulic systems, and reduce time to market. The systems feature high ingress protection ratings, making them suitable for extreme environments.

ePowerpack for lift functions

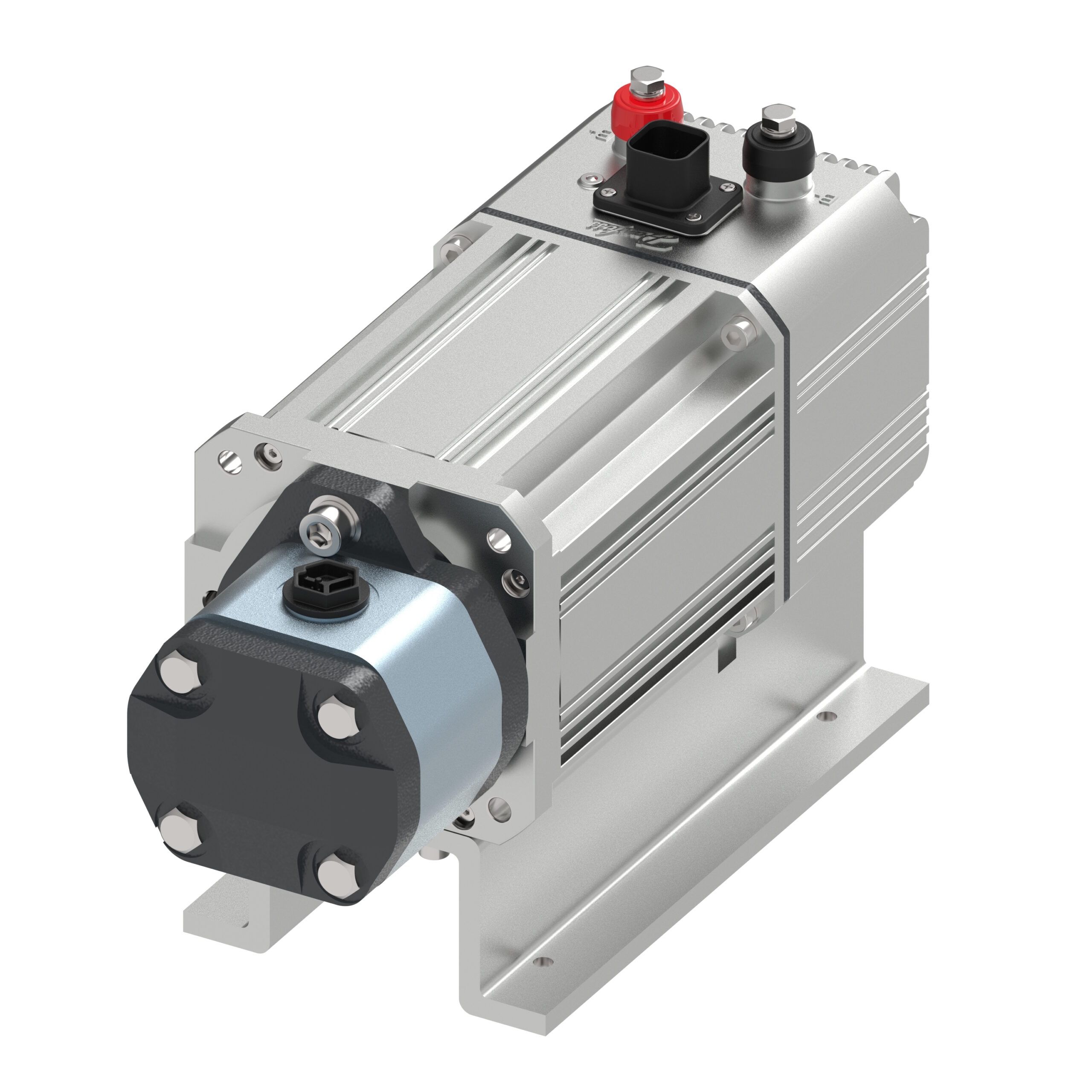

The ePowerpack is a complete system solution that powers machine lift functions. It comprises a permanent magnet electric motor, inverter, and optional hydraulic pump. The ePowerpack offers several distinct advantages. As an integrated solution, the ePowerpack simplifies and significantly reduces the number of labour hours needed for installation. Its compact design, which features fewer part numbers than a standard similar design and has no additional cables or mounting plates, further simplifies installation.

The key benefit of the ePowerpack is the efficiency gains it unlocks. Test results from the Danfoss Application Development Centre show that its innovative design, with an energy recovery option, reduces energy consumption by at least 20% compared to a standard solution. As well as lowering the number of charging hours and maximising battery runtime, this can reduce operating costs. Alternatively, customers can choose to lower design costs by reducing battery size while achieving the same number of operating hours. Whichever way customers choose to use these efficiency gains, the ePowerpack delivers lower total cost of ownership.

eDrive for propel functions

The eDrive is an integrated system solution for propel functions that consists of a permanent magnet electric motor, reduction gearbox and microcontroller unit. Designed to be the most compact drive solution on the market, the eDrive offers the same installation advantages as the ePowerpack. It also maximises system efficiency, offering peak efficiency of 94% compared to 85% for competitive AC induction motor systems. It maintains high efficiency throughout its operating range, with system efficiency 17% to 31% higher than AC systems at various speeds. Average efficiency improvement is 20%.

With overspeed protection and superior control, the eDrive delivers a smoother, better driving experience for operators. Its high controllability prevents rollback during hill starts and stops, while its high power enables gradeability of up to 30% and speeds of up to 6.4km/h in MEWPs. The eDrive is equipped with an electromagnetic braking system that is durable and replaceable along with a robust gearbox, minimising maintenance and increasing reliability.

Electrification solutions for every need

OEMs designing low-voltage applications no longer need to compromise between sustainability, efficiency, and cost. With the new Editron range of low-voltage solutions, Danfoss can offer a solution customised to individual needs. From scissor lifts and boom lifts to mini wheel loaders and excavators, Danfoss has the expertise to develop the best electrification solution for each application.

To find out more, iVT Expo visitors can meet Danfoss Power Solutions at Stand 610