At this year’s iVT Expo USA, Bosch Rexroth and HydraForce are showcasing a range of technologies including digital boom control, oil-condition monitoring, and compact hydraulic power for mobile and off-highway equipment

When Bosch Rexroth and HydraForce joined forces in 2023, they gave mobile and off-highway equipment manufacturers a richer path to designing and sourcing advanced compact hydraulic and motion-control systems. By aligning engineering expertise, application knowledge and their product portfolios, OEMs now have a single global source to reduce complexity, accelerate development, and improve machine reliability.

At the 2025 iVT Expo, the companies are spotlighting solutions ranging from advanced boom controls to real-time oil monitoring and compact hydraulic power. Visitors can also consult with Bosch Rexroth and HydraForce technical application engineers about their machine challenges and goals, whether it’s smoother machine control, safer load handling or faster system integration.

“Our goal is to help OEM customers build equipment with more precise, reliable, and energyefficient hydraulics,” says Brent Dolan, director of product line strategy, North America, HydraForce.

Expanded solutions on display

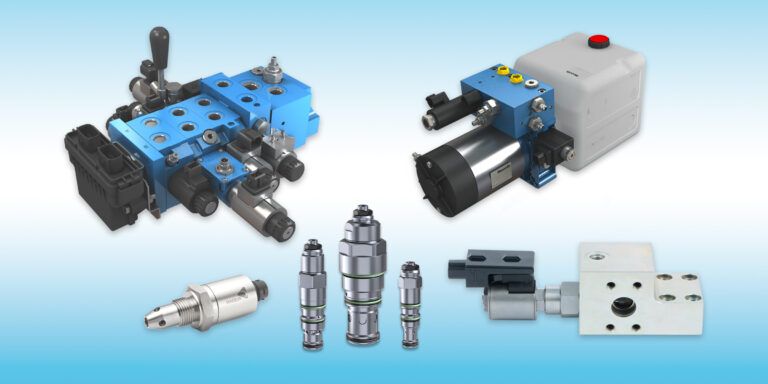

Visitors to Booth 510 can explore a lineup of solutions engineered to tackle key off-highway machine priorities. Among the highlights, Bosch Rexroth Counterbalance Valves continue to raise the bar for safe, precise hydraulic control. Designed to stabilize shifting loads even in tough conditions, these valves help reduce drift, extend component life, and support higher machine uptime.

For boom and lift applications, the HydraForce EHBL digital boom control valve manages cylinder pressure directly, eliminating pilot lines and easing integration with modern electronic controls. Field tests have shown smoother lowering, better operator feel, hose-burst protection, and measurable fuel savings. These benefits translate to more efficient, safer booms with a considerably simpler system design.

Bosch Rexroth’s EDG-OBE piloted directional valves combine compact hydraulics with closedloop electronics, maintaining precise spool positioning through CAN-based control. This supports fast, responsive movement with minimal hysteresis, delivering reliable load handling in aerial platforms, cranes, and telehandlers while reducing wiring and controller complexity.

The HydraForce Oil Condition Sensor, developed in partnership with Tan Delta Systems, gives OEMs continuous visibility into oil health. Real-time data allows for proactive maintenance, protecting key components, extending service intervals, and maximising fluid use to support sustainability and uptime goals.

For applications needing a ready-to-install hydraulic power solution, the Compact Power Module series delivers consistent pressure and flow in a compact footprint. Designed for scissor lifts, dock systems, and tailgate platforms, these units help reduce installation time and engineering effort.

HydraForce will also demo its HF-Impulse 2.0 – its free configuration and programming environment for electronic controllers. The platform supports diagram-based logic as well as C++ and structured text, giving engineers more flexibility to prototype, update, and commission machines efficiently.

Support and expertise beyond the expo

To connect with Bosch Rexroth and HydraForce technical specialists about system design goals or engineering challenges at any time, simply visit hydraforce.com.