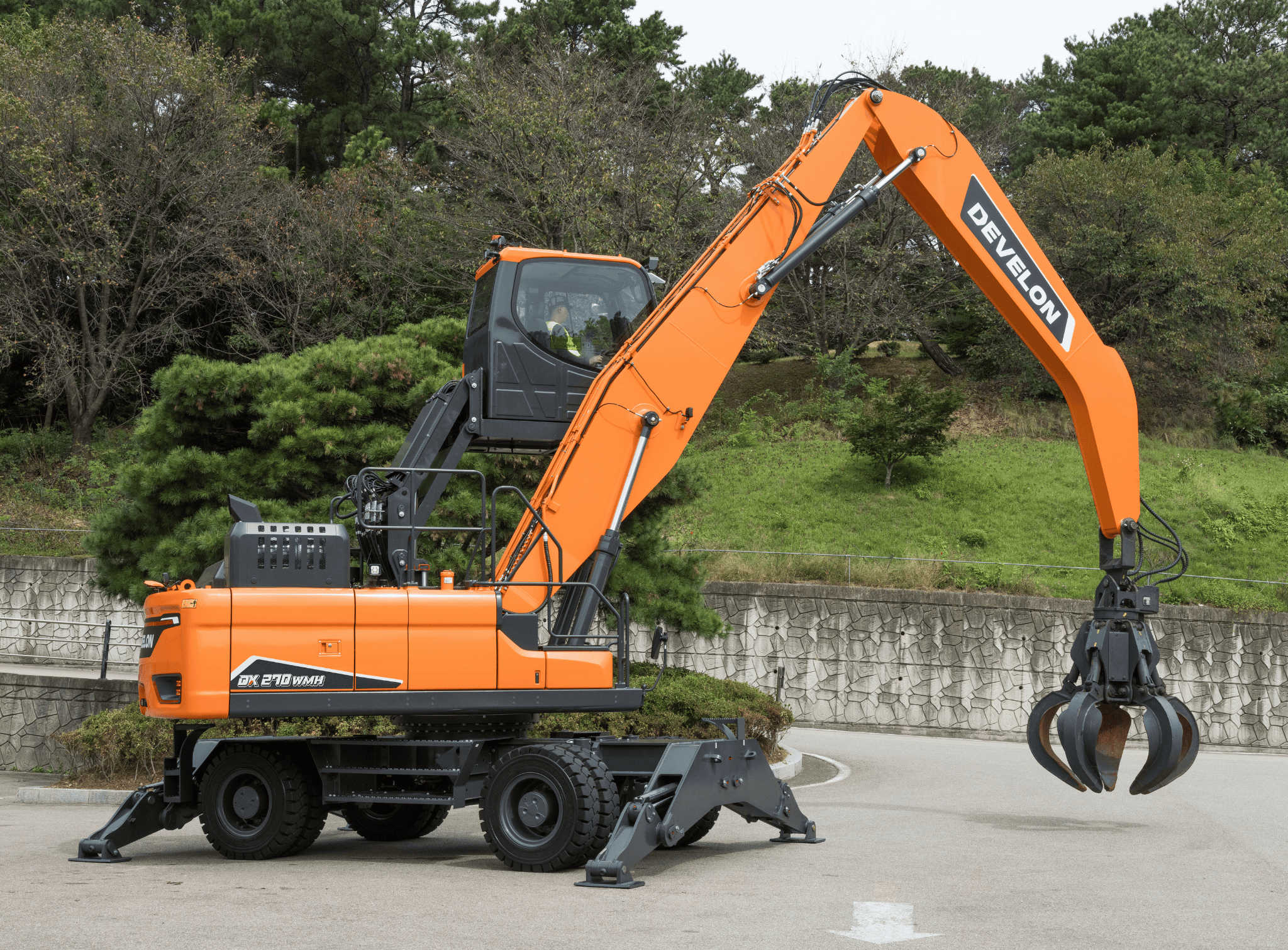

Develon has launched the new DX270WMH-7 wheeled material handler. The DX270WMH-7 is powered by the latest generation Develon 6-cylinder, turbocharged DL06V water-cooled diesel engine, providing an output (SAE J1995) of 141kW (189HP) at 1900RPM.

Incorporating new undercarriage, arm and boom, elevating cab and counterweight designs, the new DX270WMH-7 is built to offer next level performance for the toughest tasks across a wide range of material sorting and handling applications. The latter include the handling of scrap metal and other solid waste, as well as those in recycling, demolition and the timber industry.

The DX270WMH-7 has a newly designed undercarriage with heavy duty, wide axles and longer and broader dimensions, combined with a matching wheelbase to provide enhanced stability when working with the machine.

With a range of elevation increased to 2603mm, the new hydraulic cab riser design gives the operator better all-around visibility of the attachment and work area. This is combined with a faster up speed for the elevation.

The very latest DXW-7 cab design provides a comfortable interior and ergonomic layout, including an 8 inch gauge panel and smart controls provided by the very latest operating technology.

The elevating cab incorporates structural reinforcements to ensure smoother operation and provide better protection of components such as hoses and greasing lines. There are also two safety valves for emergency cab descent, one in the cab and the other on the outside.

The DX270WMH-7 offers a greatly improved performance without compromising on dimensions, with a longer reach and a higher lifting capacity, with a straight arm as standard and the options of gooseneck and long gooseneck arms as alternatives.

The straight arm configuration offers the bucket linkage and standard coupling for the use of sorting grapples. The gooseneck arms provide a cost-effective solution, for use where suspended attachments are being employed. Arms and booms have been designed specifically for material handling tasks, with the emphasis on durability and lifting stability.

The new material handler has been designed to be easy to operate with ergonomic joysticks and a steering wheel. The machine comes equipped with two-way auxiliary and rotate circuit hydraulics to improve efficiency. The operator can use buttons on the joysticks or an optional foot pedal to control auxiliary attachments.

A special Develon-developed system, Smart Power Control (SPC), improves machine efficiency while maintaining productivity through variable speed control and pump torque control, automatically adjusting RPMs according to the load being handled.

Built on years of experience with previous models, the DX270WMH-7 is engineered specifically for the demanding needs of waste and recycling operations. Its wide and stable undercarriage with individually controlled stabilizers ensures exceptional balance and durability, even in uneven or debris-laden environments. A reversing fan comes standard, helping to maintain optimal engine temperatures by automatically clearing dust and debris from the cooling system – minimizing downtime and maintenance.

To enhance operator and site safety, the machine features an innovative virtual wall system, allowing for customizable operating boundaries to prevent accidental contact with obstacles in front of the machine or with ceilings when working indoors. The system also prevents the risk of contact of the attachment and the cab with the surroundings.

Images courtesy of Develon