John Deere Electronics (booth 6045) is using this week’s iVT Expo in Cologne to showcase the commercial availability of its high-performance vision processing unit (VPU), a core component behind the company’s See & Spray technology. This powerful module, designed for rugged environments and advanced Computer Vision Machine Learning (CVML) applications, is now available to OEMs across various industries.

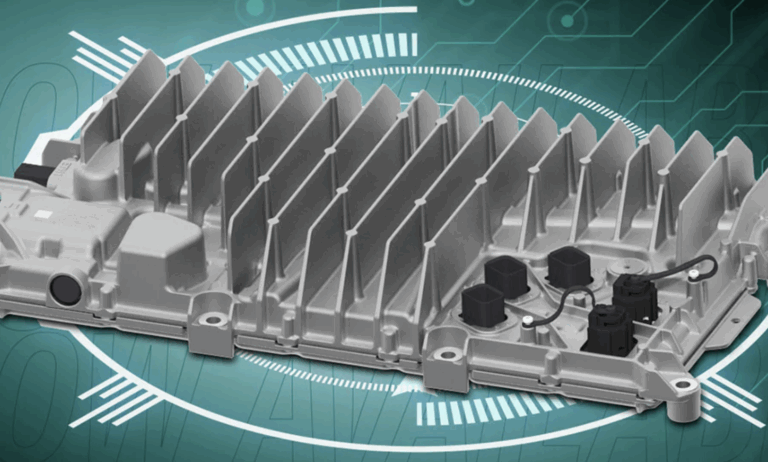

The module, previously exclusive to John Deere precision agriculture solutions, offers a high GPU- and high CPU-capable platform, enabling OEMs to integrate sophisticated vision-based automation into their own products. It features compact, powerful technology, chosen for its performance in GPU and CPU per watt and its efficient power dissipation, which is essential for demanding processing tasks. The module is also equipped with 12 ports for camera integration to enable comprehensive visual data capture.

It is engineered to withstand harsh operating conditions: boasting an IP67 rating for full submersion in water and an operational temperature range of -25°C to 50°C*. It seamlessly interfaces with vehicles and machinery through industry-standard communication protocols, including CAN and Ethernet.

“We’re proud to offer OEMs a vision processing unit that truly stands apart. We’ve engineered this module to perform in the harshest environments, focusing on robust thermal and vibration performance. Unlike others on the market, we’ve achieved this without liquid cooling or internal fans, relying on innovative air cooling and a rugged IP67-rated design,” said Nicholas Weisbeck, electronics systems module manager at John Deere. “The result is a highly reliable platform for cutting-edge CVML applications, enabling OEMs to bring advanced processing capabilities and greater autonomy to their customers while addressing the growing challenge of labor availability.”

The VPU enables OEMs to integrate the proven reliability and high performance of John Deere advanced electronics into a wide range of innovative solutions. Designed for demanding environments, this module excels in diverse applications that extend far beyond traditional agricultural uses. The 12 camera ports offer comprehensive visual data capture, facilitating such applications as operational efficiency (advanced vision systems for improved situational awareness across various vehicle and machinery types) and intelligent automation and control eg autonomous navigation, advanced robotics, and real-time image and video processing.

Beyond its robust capabilities, the VPU hardware supports comprehensive diagnostics and insights to simplify troubleshooting. These integrated diagnostics can assist in streamlining system upkeep and minimize downtime to ensure smooth operation and productivity on the jobsite.