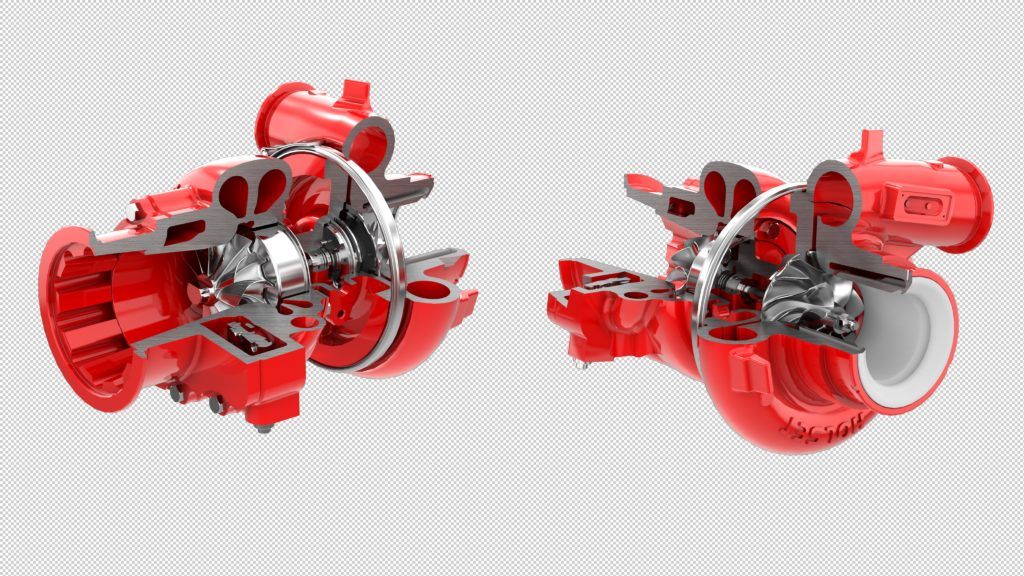

Cummins has shared some of its turbocharger knowledge at the Institute of Mechanical Engineers’ annual conference on turbochargers and turbocharging.

The company presented six papers at the conference, in London, England, reflecting the 20,000 hours of R&D it has invested in the technology

Brett Fathauer, executive director of research and engineering at Cummins Turbo Technologies, said, “With customers demanding smaller engines with greater power density, along with lower emissions, the turbocharger remains one of the most critical components on a vehicle driveline. Cummins is dedicated to constantly exploring ways to improve turbocharger design, and it is through investing heavily in advanced testing facilities and the top turbocharger engineers, that we bring real benefits to the customer.”

The six papers covered: optimizing wastegate bypass flow reintroduction for increased turbine stage efficiency; applying additive manufacturing to turbomachinery; tribological performance of coated and non-coated materials in high-temperature environments; developing a lead-free corrosion resistant bearing system for turbocharger applications; steady and transient conjugate heat transfer of a turbocharger and; and stability optimization of turbocharger rotor-floating ring bearing systems.”