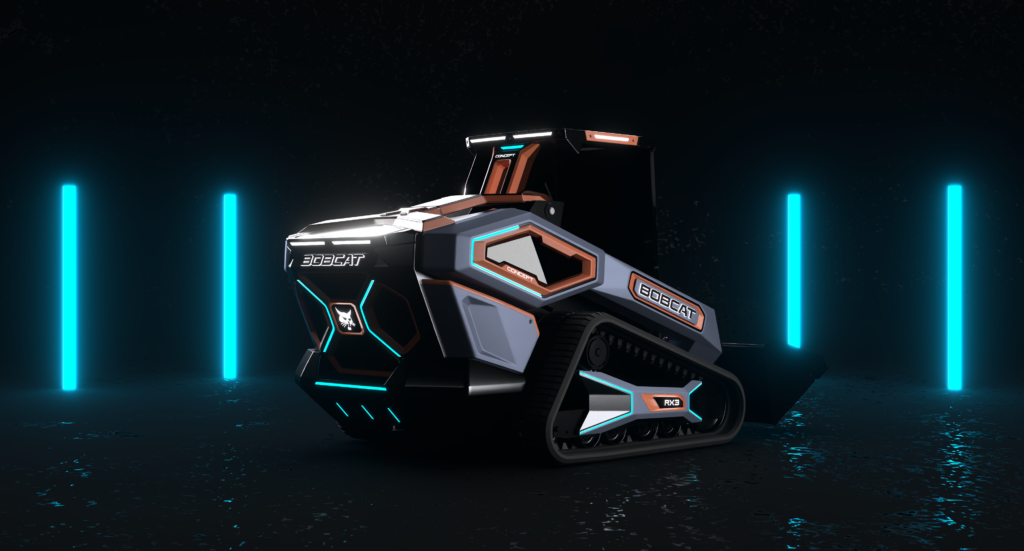

For a taste of the future, head to the Doosan Bobcat stand at Conexpo to see the RogueX3 concept which builds of previous generations by adding modularity and AI systems

ConExpo will be a sort of homecoming for Bobcat’s battery-electric RogueX3 –it was in Las Vegas at the start of the year that the machine was first unveiled to the public during CES 2026.

While CES attendees were impressed by the machine’s sleek appearance and cabless design, the dedicated construction industry audience at ConExpo will no doubt dig deeper into its autonomous capabilities and suite of artificial intelligence-powered systems designed to transform and innovate compact construction equipment operations.

Moreover, construction operatives will be particularly interested in the third-generation RogueX3’s enhanced modularity –a concept that allows the machine to be configured with or without a cab, switch between tracked or wheeled undercarriages, and adjust lift arm configurations based on specific applications.

“As workforce needs change and jobsites become more complex, we’re responding with intelligent systems that empower people to accomplish more, faster and smarter,” says Scott Park, chief executive and vice chairman of Doosan Bobcat.

While demonstrated in electric form, the platform’s flexible architecture also supports multiple power options including diesel, hybrid and hydrogen configurations.

Powering all of Bobcat’s electric equipment portfolio is its Bobcat Standard Unit Pack (BSUP), a modular battery system engineered for harsh environments, which is also made available to other OEMs. The stackable units accommodate space constraints typical of compact equipment while offering scalability across the product range.

Central to RogueX3 is Jobsite Companion, an on-machine AI feature that employs a proprietary large language model to deliver voice-activated control and guidance, automating over 50 machine functions while operators maintain control of primary systems. Critically, the technology operates independently of cloud connectivity, addressing the frequent connectivity limitations encountered on construction sites.

“Jobsite Companion lowers the barrier to entry for new operators while helping experienced professionals work faster and more precisely,” says Joel Honeyman, vice president of global innovation at Doosan Bobcat. “It’s not just smarter technology; it’s a smarter experience that puts expert-level guidance directly in the cab.”

Further enhancing operator experience on the cabbed version of the RogueX3 is an advanced display system incorporating transparent MicroLED screens integrated into cab glazing. These overlay 360-degree camera feeds, performance metrics and asset tracking information directly within the operator’s sight line.

“It’s not just smarter technology; it’s a smarter experience that puts expert-level guidance directly in the cab”

Doosan Bobcat also used the RogueX3 to introduce Service.AI, an artificial intelligence platform providing technicians with instantaneous access to repair procedures, diagnostic protocols and historical service data, which aims to reduce equipment downtime.

While the RogueX3 is for the moment purely a concept machine, it serves as a showcase for several patent-pending innovations that are certain to find their way into production machines soon. “These innovations aren’t concepts for the distant future; they’re advancements that are shaping how work gets done right now,” says Park. iVT

This article first appeared in the February/March edition of iVT