John Deere’s brand new 500R sprayer will be unveiled for the first time at Agritechnica. A complete redesign positions the cab right at the front, does away with CANbus in favour of ethernet, and creates a platform with a host of automated and precision farming features which are ready to use now and will be built upon in the future. iVT finds out about the thinking behind the new design and the challenges that had to be overcome to deliver this future-ready machine

When John Deere’s engineering team analysed their European sprayer lineup in 2019, they faced a critical decision: upgrade their existing platform or start afresh. The answer came down to one fundamental factor – the position of the cab limited its maximum size… and so began the process of designing a completely new vehicle.

“Customers were telling us they wanted a bigger cab. The market, especially in UK and Germany, really demanded that,” says Mark James, John Deere’s sprayer specialist for Northern England, Scotland, and Ireland, who was part of the original five-person team that developed the specification for what would become the 500R.

The new vehicle debuts at Agritechnica this November: a completely reimagined selfpropelled sprayer to replace the previous R41 range, that shifts the cab from mid-chassis to the front, creating a new experience for the operator in terms of cab access, visibility and space.

Assembled in the company’s Horst factory in the Netherlands, there are two models in the line up – a 550R and the 540R – with tank capacities of 5,000 litres or 4,000 litres respectively. Both have the option of a 30m or 36m steel boom. The first 500Rs are expected to reach customers om Europe from summer 2026, with the main markets being the UK, Ireland, Germany and France.

The design challenges

The engineering challenge of moving the cab forward went beyond simply working out how to bolt it to the front of the chassis. One of the critical problems with designing a sprayer comes in perfecting weight distribution.

“Weight distribution of our predecessor machine was, in the worst situation – boom out, tank full – about 60/40, with 60% on the rear end,” says James. “From a sprayer perspective, you want to get to around a 50/50 weight split.”

This balance is critical for soil protection and hill-climbing capability. When a rear-heavy machine operates on slopes, it loses traction on the front wheels as weight shifts backward. The 500R’s solution places the engine at the rear of the machine – though still within the wheelbase – while positioning the tank well forward in the chassis.

“The weight of the tank really counterbalances the boom when you’re in operation,” says James. “In its worst-case scenario (full tank with boom extended), the 500R achieves a 48/52 front-to-rear weight distribution, becoming slightly noseheavy when empty and on the road.”

This configuration also delivers an additional benefit: exceptional cab quietness. “You’ve got a whole tank full of liquid between the engine and the operator station,” says James. “The noisiest thing in the cab is probably the cooling fan, if you turn it up.”

Interestingly, the design team did consider alternative configurations, including placing the engine beneath the cab or under the front of the tank. “With all of those situations, there were compromises in terms of weight distribution, but also a compromise around service access,” says James. The chosen rear-engine layout, while unconventional, provides optimal serviceability – crucial given the potential impact of service requirements during critical spraying windows.

In the past sprayer cabs have always been positioned centrally within the wheelbase of spraying vehicles in order to ensure the most comfortable ride. Putting the cab on the front of the 500R created a further challenge for engineers in matching the smooth ride of the predecessor R41 range, but this has been achieved in nearly all use cases thanks to the advanced air suspension system.

The suspension system, sourced from John Deere’s larger US-built sprayers produced at Des Moines (where the company builds approximately 7,000 machines annually), features air springs positioned within the wheel envelope.

James says the only case where the R41 might still have the edge would be running fast on a road and going over a speed bump. “It’s the compromise that you have to make,” he says. “But the end result is you get a bigger cab with room to stretch your legs, and you get a fridge in it, and you get more storage space and a plush seat.” Up sides that very much meet the market demands in this sector.

In the process of working on improving the ride, designers tried an actively controlled seat in the cab, but counterintuitively this was not a success. “When we tested that, the active seat made the ride worse, it didn’t make it better,” says James.

Despite the radically different look, the 500R does preserve successful elements from its predecessor. The dual-beam, torsion-rigid chassis design remains fundamentally similar, though extended with the front platform. “If you strip it all back to its chassis, the chassis looks very similar,” says James, representing this vehicle range as an evolution of proven engineering rather than change for its own sake.

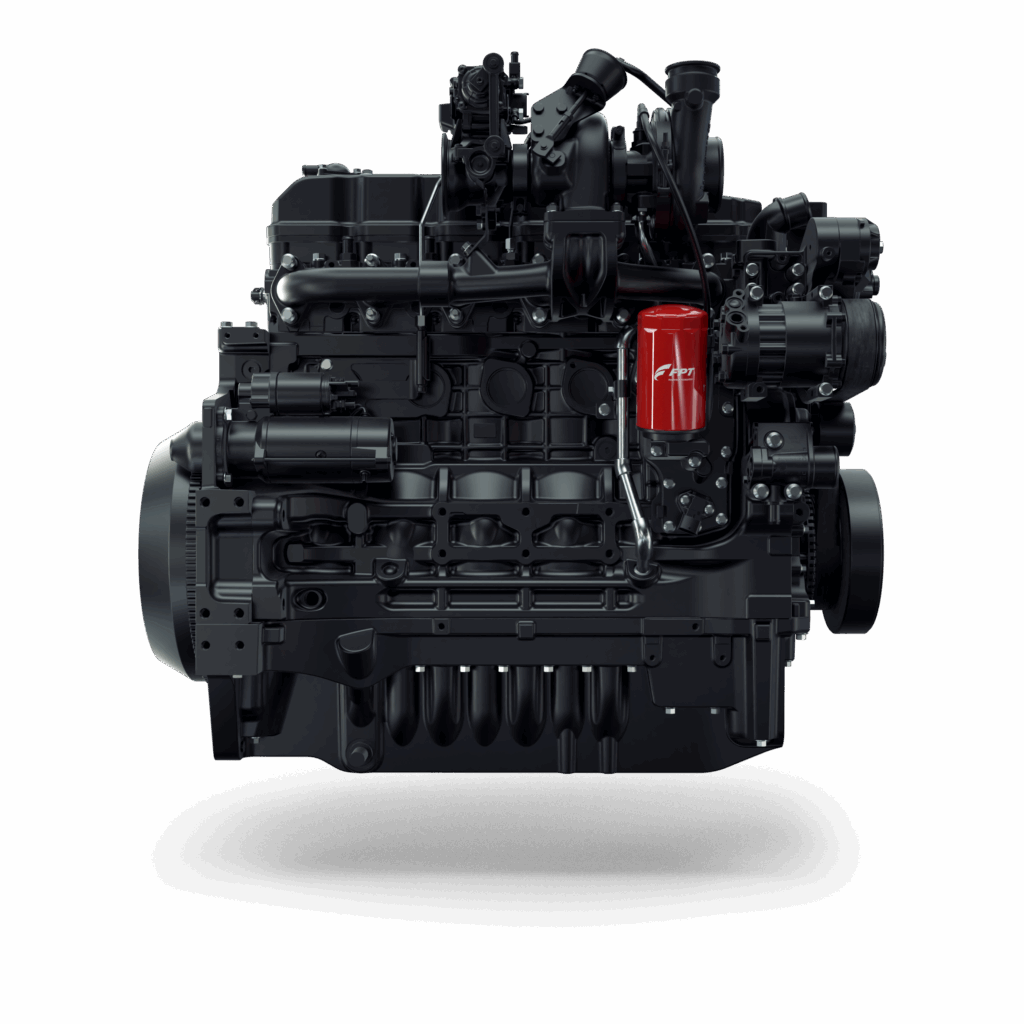

Other technologies have been strategically incorporated from across the John Deere product line, meaning that components with proven reliability over millions of hours of service can be used, despite the fact that the sprayer market is low volume. For example, the 6.8-litre dual-turbo engine, rated at 300 horsepower with intelligent power management boost, comes from the company’s bestselling 6R tractor. “We know it’s very reliable, and we know it performs very well,” says James.

John Deere partnered with key component suppliers including Sauer- Danfoss for hydrostatic drive motors, pumps, and steering valves; Bonfiglioli for final drives; Hypro for the spraying pump with ForceField seal technology for run-dry protection; and Banjo for filling pumps and electronic valves.

CANbus to Ethernet

While innovative position of the cab is eye-catching, within the vehicle’s electronic comms architecture there is another difference which, though invisible to the casual exterior observer, is no less significant. “This isn’t a CANbus machine any longer,” says James. “The communication between the individual controllers on the machine is by Ethernet.”

This shift is driven by the need for faster data transmission and larger data volumes, particularly for technologies like John Deere’s See & Spray precision application, which is likely to be integrated into the 500R range in the future. “You couldn’t just take that from the US machines and put it onto our old European machine because it is unique,” says James. Rather than upgrading old electronic architecture, the data demands of the system inspired the complete redesign. The new system runs the same software as American sprayers, featuring an appbased interface on the G5Plus in-cab screen, rather than fixed run pages. “You’re not scrolling through lots of menus, the to find the information that you want. It’s just there in front of you,” says James.

To aid precision agriculture, the 500R comes with an integrated StarFire 7500 receiver built into the cab roof as standard, providing ±10cm positioning accuracy. This is connected to the John Deere Operations Centre, enabling farmers and contractors to plan applications in advance and send the required information to the sprayer.

This can include field guidance lines and boundaries, or the name of the product and volume to be applied, with real-time progress and a record of all applications stored automatically.

Spray what you want

The PowerSpray solution system, a European-developed technology now being rolled globally, eliminates pressure regulators entirely. Instead, it controls spray pump speed directly, reacting “four to five times faster than a machine with a pressure regulator,” according to James.

The system includes fully automated rinsing with three modes, automated agitation that adjusts to tank levels, and the AirRinse system that uses compressed air to evacuate residual chemical from various circuits as the tank empties.

With a 95% take rate, the ExactApply nozzle body system provides individual nozzle switching at 50cm spacing, automatic or manual switching between two nozzle types, and pulse width modulation (PWM) for flow rate control without pressure changes.

“PWM gives us the ability to set the pressure and droplet size,” says James. Lower pressure creates larger droplets for drift reduction, while higher pressure produces finer droplets for better coverage. The system also provides turn compensation, adjusting flow rates across the boom width during turns.

“This new [electronics] architecture will be a worldwide standard”

A recent breakthrough enables different application rates across the boom width. “Previously, we had to apply one rate across the whole 36 metres. Now we have the ability to split that into 11 different sections,” says James, “which is quite a big deal for precision agriculture.”

Future-Ready Platform

See & Spray integration is “probably about two years away” pending field testing, but the 500R is ready for increasing automation. Turn automation via GPS triggering is coming soon as part of the autumn software update. “At that point, the operator is just minding the turn. They’re not actually doing anything,” says James.

Other key automated functions of the 500R include boom lifting. “This is pulling the boom tips up so they don’t hit the ground as you turn,” says James. “And this now incorporates the forward speed of the vehicle, so the vehicle slows down automatically. When you come out of the turn, it will put all these things back again and automatically engage the AutoTrac to steer the machine down the field.”

With so many automated functions, is a future where the operator is removed completely now within sight? James says that no official timeline exists for fully autonomous operation, but acknowledges the 500R provides a capable platform. “The bit that we would need to add would be the safety and protection systems. For example spotting a person in the field that might be near or obstructing the path of the machine,” he says.

These safety systems represent the primary technical hurdle rather than the automation technology itself, with Ethernet architecture ensuring the 500R can rapidly adopt emerging, data-heavy technologies. “This new architecture will be a worldwide standard,” predicts James.

As John Deere prepares for the 500R’s public debut at Agritechnica, the machine stands as both a response to immediate market demands and a platform for future innovation. The combination of proven components, revolutionary communication architecture, and thoughtful design decisions positions it to serve European farmers well into an increasingly automated and precisionfocused future.

This article first appeared in the October issue of iVT