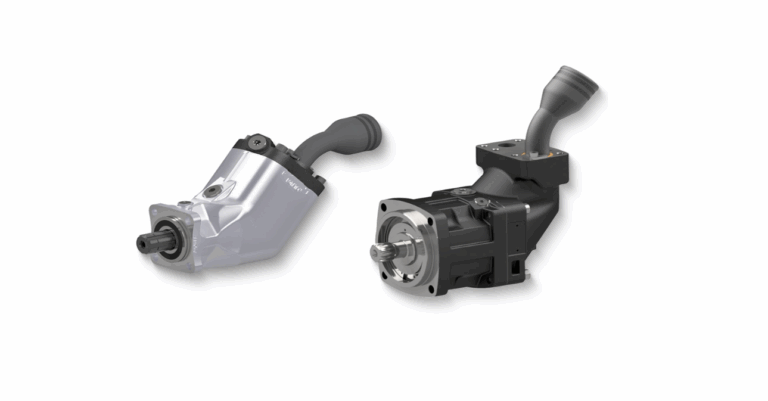

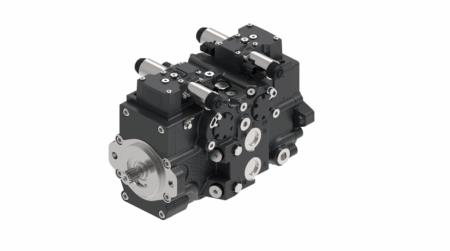

Parker Hannifin has launched its new F1e and F12e hydraulic pumps, specially designed for variable speed drive applications.

According to the company, the F1e and F12e pumps offer highly efficient hydraulic control within a system, ensuring optimal performance in electric-driven applications.

The technology behind the F1e and F12e pumps allows for a wide range of operating speeds, maximising the flow while lowering the torque. When paired with asynchronous or synchronous electric motors and controlled by frequency controllers, Parker Hannifin says these pumps operate with exceptional efficiency and reliability, leading to energy savings.

“The launch of the F1e and F12e hydraulic pumps marks a significant milestone in Parker’s commitment to driving the electrification of heavy-duty machinery,” says Fredrik Magnusson, business development manager at Parker’s Pump & Motor Division Europe. “These pumps deliver exceptional efficiency and reliability across a wide range of operating conditions, enabling our customers to reduce emissions without compromising performance. By integrating advanced technologies that minimize energy loss and noise, we are helping to pave the way for a cleaner, quieter, and more sustainable future in hydraulic systems.”

Parker’s F1e and F12e pumps are designed to integrate seamlessly with contemporary electric systems, including hybrid and fully electric vehicles.

The F1e and F12e pumps are engineered to reduce pressure pulsation, which can cause vibrations that lead to unwanted noise in the hydraulic system. By reducing these pulsations, Parker says it enhances the overall performance and user experience of hydraulic systems, creating a quieter and more reliable solution.

Image: Parker Hannifin