The Fétis Group is launching Kinell, a new brand representing the group’s low-carbon and automation activities across Europe and North America.

Kinell’s ambition is to offer a complete ecosystem of solutions to support the energy transition in off-highway machines, special vehicles, professional marine and electric power. This ecosystem will span the entire energy cycle—from generation to storage to consumption.

These energy solutions will be complemented by digital services that optimise asset management, boost productivity, and reduce total ownership costs.

In May, the first stage of the rollout focused on the electrification and automation of off-highway machines and special vehicles. This initiative brings together Fétis Group operations in Germany, France, Spain, and Canada, which previously operated under the Dintec name.

In Q3 and Q4 2025, the group will announce additional capabilities in solutions for the decarbonisation of professional marine vessels and decarbonised energy generation and storage

In parallel, the group is ramping up investment in expanding its suite of digital and engineering services.

“In the 20 years since our system integration business was founded, we’ve partnered closely with OEMs to bring their machines to life. This capability is now central to our strategic vision. As we expand geographically and broaden our offering, we need a unified international brand that reflects our ambition and supports our growth,” says Oliver Lythgoe, chief marketing officer of the Fétis Group.

Kinell is optimistic about the long-term potential of low-carbon solutions in its key industries. With the rapidly falling cost of renewable energy and downward pressure on battery prices, electrification is becoming not only the lowest-carbon option but also the most productive and cost-effective over a machine’s lifetime.

Automation is also set for strong growth, driven by industry-wide shortages of skilled operators and increasing demands for safety and efficiency. These trends are closely linked to the shift toward electrification.

For the initial offering in off-highway machines and special vehicles, OEMs face three key challenges in the shift to low-carbon and autonomous technologies, and the company says it is positioned to help overcome them.

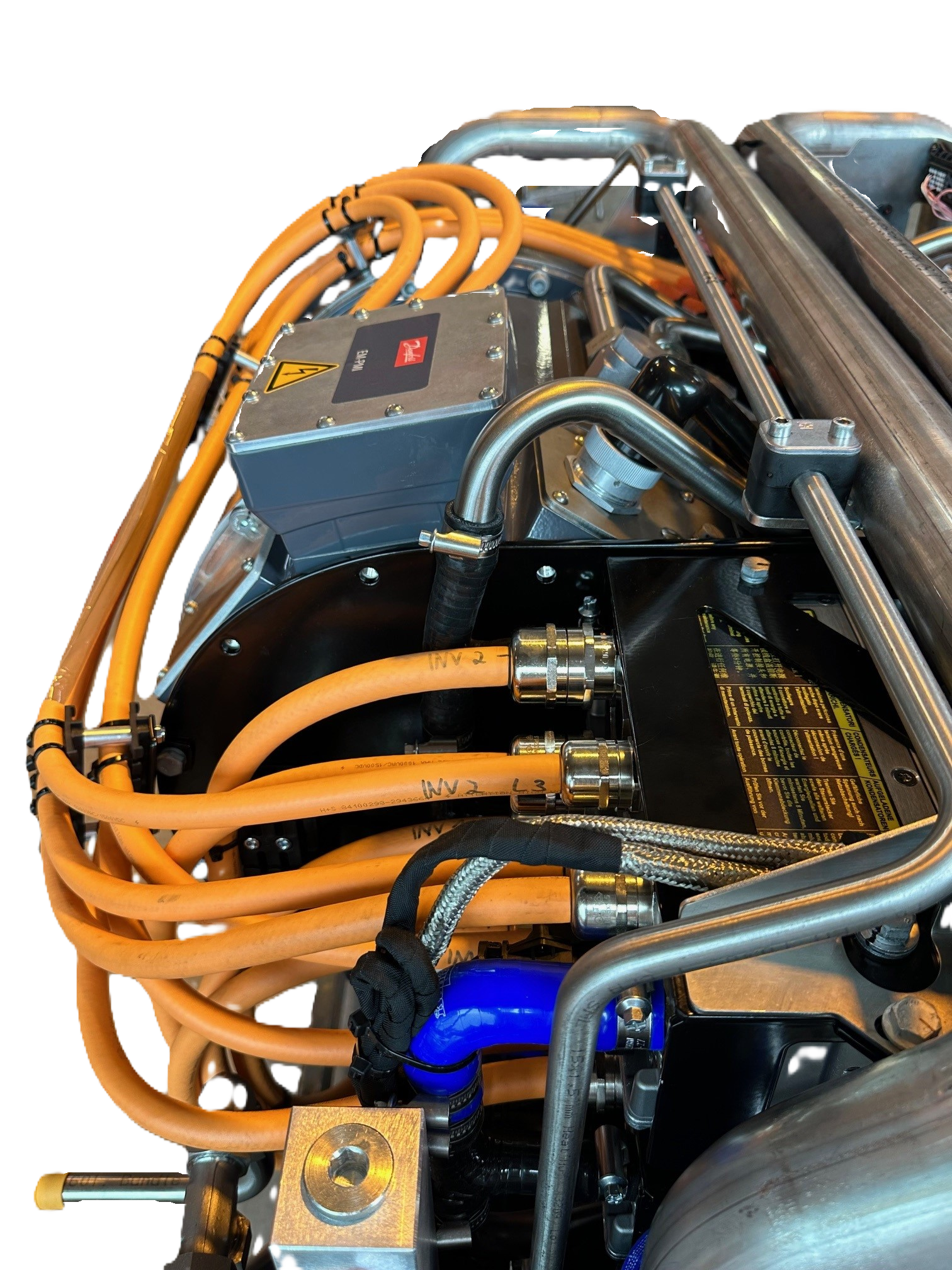

In terms of engineering expertise, many OEMs lack in-house experience in high-voltage, high-current electrical architectures. By partnering with Kinell’s engineering teams, OEMs can reduce risk, accelerate development timelines, and optimise system costs.

Kinell also offers engineering services in controls, software, mechanical systems, and prototype development—designed to complement and enhance OEMs’ internal capacity.

Electrification is more than propulsion. Kinell provides pre-engineered system solutions such as electric power take-off drives (ePTO), charging systems, and power management platforms, which help OEMs deliver complete machines more efficiently.

Software and control systems for off-highway machines are expected to grow dramatically more complex over the next five years. Customers demand ever more productivity, efficiency, safety, and asset management features. Economically and technically, it makes sense for OEMs to integrate externally developed, pre-validated software modules, enabling internal teams to focus on what sets their machines apart.

Kinell’s software portfolio will include modules for vehicle path planning, autonomous steering, and connectivity solutions such as telematics and precision farming.

While the market already offers a wide range of electrification components—batteries, motors, inverters—OEMs still need reliable, cost-effective sources for application-specific components. These include wiring harnesses, power distribution units, and machine-specific software. Kinell delivers these with quality and responsiveness.

“As we bring together the capabilities of our international teams, we’re uniquely positioned to support ambitious OEMs in solving the toughest engineering challenges. Yes, we have deep technical expertise—but just as importantly, we’ve proven our agility in a fast-changing market. We’re committed to investing in our future and helping OEMs bring the next generation of machines to life,” concludes Lythgoe.

Images courtesy of Kinell