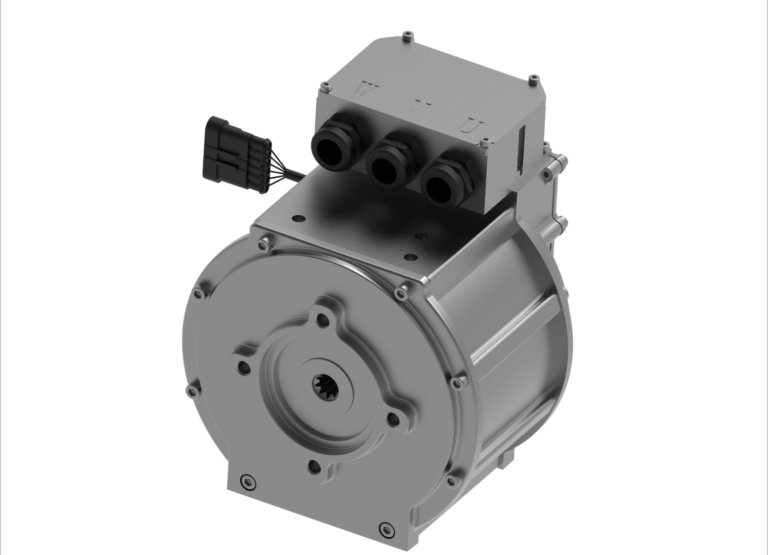

At Agritechnica, Danfoss Power Solutions has launched its Editron EM-PMI180 low-voltage electric motor.

The 48-volt synchronous reluctance assisted permanent magnet (SRPM) motor is designed to drive a hydraulic gear pump in compact electric machinery, powering the machine’s work functions.

The PMI180 motor features a compact, robust design delivering high power density and efficiency. Ideal applications include boom lifts, scissor lifts, and compact loaders and excavators.

Most manufacturers of mobile elevating work platforms (MEWPs) utilise AC induction motor (ACIM) systems to drive the hydraulic pump powering the machine’s lift function. These motors are bulky and inefficient, and today many MEWP manufacturers are switching to newer SRPM technology.

Compared to ACIM, SRPM technology offers higher torque, higher power, and a more compact design. The Editron PMI180 motor exemplifies this difference, delivering greater efficiency and torque in a smaller envelope than typical AC induction motors. The PMI180 features hairpin windings, which further increase motor power density and efficiency compared to conventional round wires.

The PMI180 motor features a 15% smaller envelope than AC induction motors with the same torque/power. With an outer diameter of 180 millimeters, the PMI180 motor’s compact size simplifies machine integration. This is particularly important in small electric machinery in which the battery pack occupies most of the available space, leaving little room for motors, inverters, hydraulics and other components.

PMI180 offers 15% greater efficiency than AC induction motors. This higher efficiency extends the runtime of electric machinery or enables the use of a smaller, less expensive battery pack to achieve the same runtime.

The robust design of the PMI180 enables the motor to be used in harsh conditions. The motor and connector feature an IP67 rating, providing protection from dust, dirt, and moisture ingress. The motor’s corrosion resistance has been validated in a 200-hour salt-spray test, offering extended protection. Combined, these features can increase the motor’s service life, even in extreme environments.

“Editron has long been known for its high-voltage electrification solutions. Now we are strategically building out our low-voltage product lines to encompass 24- and 48-volt solutions,” says Eric Wang, application engineering and portfolio manager, Editron China, Danfoss Power Solutions. “PMI180 is built on advanced technology, a proven product development process, and decades of mature, global manufacturing and quality control, which means the motor is not only state of the art, but also highly reliable and built to last.”

The Editron PMI180 motor features a rated power output of 7kW at 48-volts DC. Its rated speed is 3,000rpm and its maximum speed is 4,000 rpm. Rated torque is 22.5 Nm while maximum torque is 90Nm. It features a standard gear pump interface for connection to pumps up to 16 cc at 240 bar. The PMI180 works with the EC-C48 inverter, which will be available in 2026.

In addition to the PMI180, the ED-DT180 eDrive will be added to the Editron 48-volt portfolio. The eDrive is a propel solution for MEWPs and similar off-highway vehicles that integrates an electric motor, reduction gearbox, and electromagnetic brake in one compact package.

Designed to be the most compact drive solution on the market, the eDrive simplifies machine integration while maximizing system efficiency and delivering a smoother driving experience for operators. The 48-volt system joins the 24-volt system launched in 2024. With the availability of PMI180 and DT180, original equipment manufacturers can create complete propel and work function systems for electric MEWPs.

Image: Danfoss Power Solutions